JUNIOR YEAR STUDIO PROJECT AT ASU

DESIGN BREIF

To operate as a wet and dry vacuum intended for home use in floods, spills, and everyday messes.

USERS

In the preliminary phase, four interviews were conducted in order to get a better understanding how wet/dry vacuums are used. The main purpose of which, to find problems with existing models in the market.

Matt Blaustien, 20

Ram Gupta, 20

Dylan Kohn, 22

Ryan Filan, 20

“Wish it came with different nozzles that can fit different angles.”

“A brush or sponge to remove stains from debris and liquid tank.”

“The vacuumed dirt gets picked but then contaminates clean water and then spreads dirty water everywhere.”

“Too big, very hard to move around, very loud, splashes everywhere.”

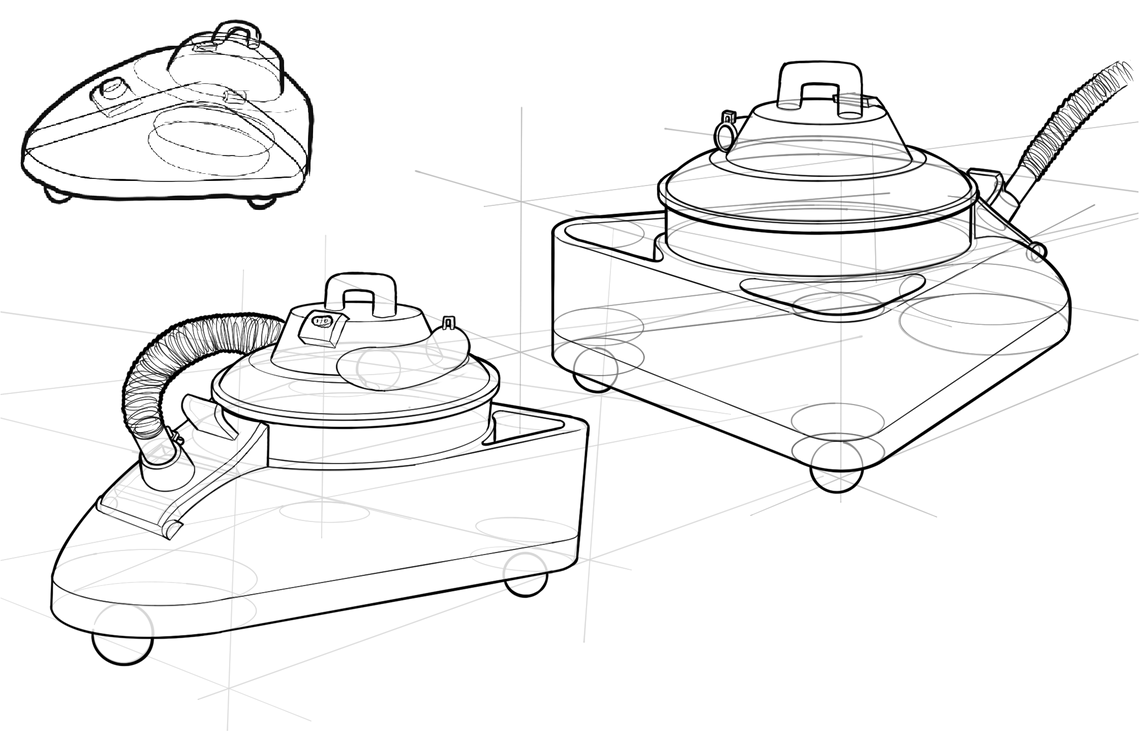

SKETCHES

In sketching, it was crucial to incorporate the mechanics and machinery of existing industrial shop vacs into a potential residential product. Once thirteen potential forms were ideated, it was time to further develop three concepts that I believed would be best suited for home use.

HVAC Sketches

HVAC Sketches

CONCEPTS

As I moved forward with conceptualizing the HVAC, I decided to pick three designs to further develop. The criteria used in picking these designs included functionality, form, and how each component would fit within the housing.

FINAL DESIGN

There was an issue...

One thing I learned during CAD modeling was how the size of a wheelbase would impact functionality. A small wheelbase would make a vacuum unstable and easy to topple over. Another was the components necessary for attaching the hose to the vacuum body. Users tend to use the hose to pull a vacuum. I needed to design a way to keep the hose attached to the machine while also enabling the user to remove the hose simply. To address this I included a notch on the hose, which, when inserted and twisted into the body, prevented the hose from separating from the vacuum body. I also included a storage bin for organizing attachments and alternative nozzles.

The final elements of my design were intended to address aesthetic qualities. I used magnets to seal the motor housing to the main bucket. This eliminated the need for bulky clamps. I also selected colors to convey cleanliness: an aluminum bucket, a dark blue motor housing with turquoise highlights and gray branding.

.png)